Proven Design for Joints

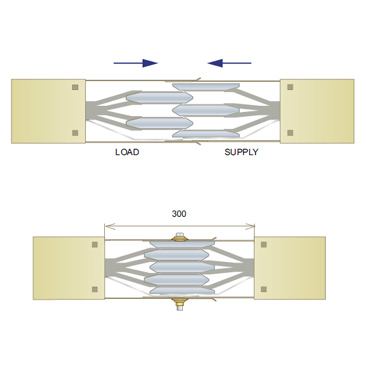

Joint facilitates physical and electrical connection between busway units to complete point to point distribution system. They also play an important role in ensuring satisfactory performance of the system. Under normal current carrying conditions, heat is generated at conductor contact area due to their contact resistance. Effective management of this heat, either by reducing or transferring it to external environment is essential for safe operation and extended life of entire system.

View this, direct male-female type jointing system having lesser hot spots (contributing largely in reducing temperature rise at joint areas) has been adopted by us. Besides this, we have provided advanced arrangement similar to heat sink design at joint areas, it is found beneficial for faster heat dissipation. We have also provided special insulators having adequate thermal resistance at contact areas, these insulators and method of joining conductors needing connection, ensure quick transfer of heat from core of the joint to the external housing. These are few key points of our design which help in reducing overall temperature of joint and extend life of system.

Our Design also eliminates possibilities of incorrect jointing. Proper assembly and installation of joint can accommodate + 3mm thermal expansion of conductors.

Insertion and Removal of any section of feeder or busway unit, by removing joint bolts has been made easy by using self-guided joint bolts and arrangement of insulation barriers which ensure integrity of system during such insertion and removals.

“UL” Certified Material has been used for Insulation Barriers fitted alongside conductors at Joint Area and they have also been type tested at UL to verify their performance and withstand capacity in case of temperature rise. To ensure increased level of safety they have also been verified for their performance while offering resistance to fire.